High-quality metrology for quality control in the measuring room, production, incoming goods and development.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

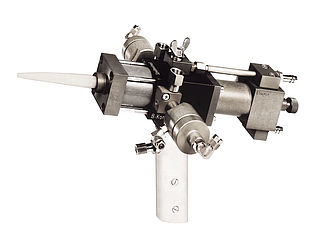

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

Proven use for decades to spin finest yarn: planetary spinning pumps are the heart of every synthetic fibre spinning plant.

Spin finish dosing pumps do not only meter preparation fluids. They can also be used for the consistent dosing of water, perfume or even oils.

There are almost no limits to the use as a dosing pump in various industries. As a spinning pump it is only used for special applications.

Predominantly used in spinning and adhesives technology, they offer the possibility of realizing two flow rates with minimal space and one motor drive only.

Product bores which are on both sides of the pump body allow the pump to be integrated directly into the production line.

They can be used for all applications. Direct installation in the product line does not require an additional clamping block.

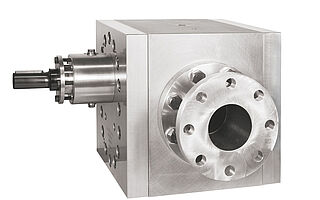

Discharge pumps ensure gentle discharge of polymer melts with low product shear. Booster pumps ensure a defined process pressure for downstream tools such as dies or extruders.

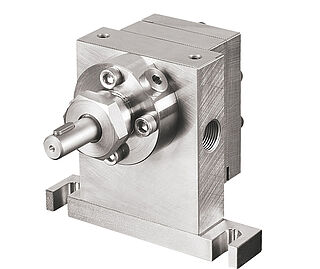

For highly accurate, low-pulsation dosing of liquids. The gear metering pumps achieve an efficient performance even at low viscosity and back pressure.

Paint metering pumps can also be used for robot applications. Even at short flushing cycles these pumps show excellent flushing results.

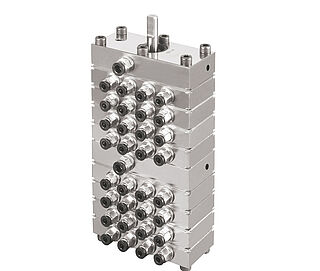

Solutions for material preparation, conditioning and supply to the meter mix dispense machine.

Lightweight design:

2C - 3C Meter Mix Dispense Machine for low flow rates

Our allrounder:

1C - 4C Meter Mix Dispense Machine for low to medium flow rates

Compact and efficient:

2C - 4C Meter Mix Dispense Machine with an output of up to 10 l/min

High-capacity:

2C - nC Meter Mix Dispense Machine for high material flow rates

Customised solutions:

perfectly tailored to suit your application

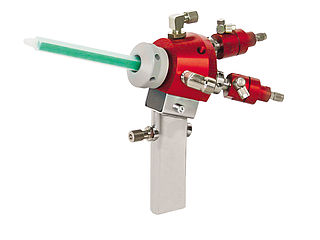

The mixing takes place exclusively through the flow movement of the components and the geometry of the mixing element.

The components are mixed by a rotating element in a mixing chamber.

The mixing takes place through the flow movement of the components in cooperation with the geometry and rotation of the mixing element.

Legal Information

Mahr Metering Systems GmbH

Carl-Mahr-Str. 1

D-37073 Göttingen

Phone: +49 551 7073 100

MahrMeteringSystems@mahr.com

Court of registration: Göttingen Local Court

Commercial register number: HRB No. 3377

VAT identification number according to §27a of the VAT Act:

DE813264663

Managing Directors: Dr. Lutz Aschke, Dr. Reiner Karl

Responsibility in terms of press law and the German Telemedia Act is borne by:

Mahr GmbH, Carl-Mahr-Straße 1, 37073 Göttingen, Germany

Phone: +49 551 7073 800

webmaster@mahr.com

Mahr cannot be held liable for links to other websites

With the decision of 12 May 1998 – 312 O 85/98 – "Liability for External Links", the Landgericht (Regional Court) in Hamburg declared that anyone creating an external link is deemed, where applicable, jointly responsible for the contents of the linked site. This can – according to the court – be avoided by expressly distancing oneself from these contents.

Therefore as a precautionary measure Mahr GmbH hereby distances itself from the contents of all pages linked to this website.

Copyright notice:

The photos and graphic designs used on this website are protected by copyright. If you want to use any of them, please contact the site operator. The operator will then, if necessary, establish contact with the author or authorized user.

The images used on this website are from the following sources: Mahr GmbH, stock.adobe.com, istockphoto.com. The name of any other authors appears near the respective image.