High-quality metrology for quality control in the measuring room, production, incoming goods and development.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

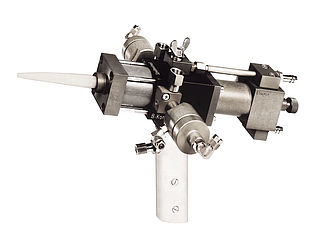

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

Proven use for decades to spin finest yarn: planetary spinning pumps are the heart of every synthetic fibre spinning plant.

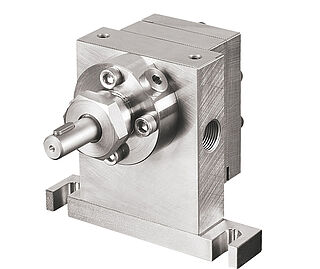

Spin finish dosing pumps do not only meter preparation fluids. They can also be used for the consistent dosing of water, perfume or even oils.

There are almost no limits to the use as a dosing pump in various industries. As a spinning pump it is only used for special applications.

Predominantly used in spinning and adhesives technology, they offer the possibility of realizing two flow rates with minimal space and one motor drive only.

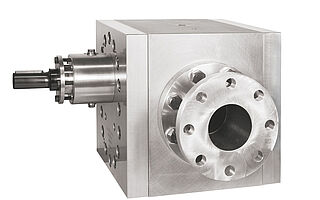

Product bores which are on both sides of the pump body allow the pump to be integrated directly into the production line.

They can be used for all applications. Direct installation in the product line does not require an additional clamping block.

Discharge pumps ensure gentle discharge of polymer melts with low product shear. Booster pumps ensure a defined process pressure for downstream tools such as dies or extruders.

For highly accurate, low-pulsation dosing of liquids. The gear metering pumps achieve an efficient performance even at low viscosity and back pressure.

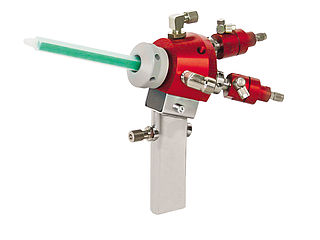

Paint metering pumps can also be used for robot applications. Even at short flushing cycles these pumps show excellent flushing results.

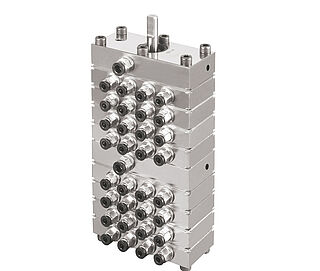

Solutions for material preparation, conditioning and supply to the meter mix dispense machine.

Lightweight design:

2C - 3C Meter Mix Dispense Machine for low flow rates

Our allrounder:

1C - 4C Meter Mix Dispense Machine for low to medium flow rates

Compact and efficient:

2C - 4C Meter Mix Dispense Machine with an output of up to 10 l/min

High-capacity:

2C - nC Meter Mix Dispense Machine for high material flow rates

Customised solutions:

perfectly tailored to suit your application

The mixing takes place exclusively through the flow movement of the components and the geometry of the mixing element.

The components are mixed by a rotating element in a mixing chamber.

The mixing takes place through the flow movement of the components in cooperation with the geometry and rotation of the mixing element.

Disclaimer

1. Content of the online offer

The author accepts no responsibility for the topicality, correctness, completeness or quality of the information provided. Liability claims against the author based on material or non-material damages caused by the use or non-use of the information provided or the utilization of erroneous and incomplete information are fundamentally excluded to the extent that it cannot be demonstrated that the author acted in a willful or grossly negligent manner.

All offers are subject to change and non-binding. The author expressly reserves the right to change, supplement or delete parts of the site or the entire offer without special notice or to temporarily or permanently discontinue the publication.

2. References and links

As regards direct or indirect references to external Internet sites ('links') which are outside the author's area of responsibility, liability would only be assumed if the author had knowledge of the content and if it was technically possible and feasible for the author to prevent their use in the case of illegal content.

The author hereby expressly declares that at the time the links were created, no illegal content was discernible on the linked pages. The author has no influence whatsoever on the current or future design, content or authorship of the linked pages. Therefore, the author hereby expressly distances himself from all contents of all linked pages that were changed after the link was created. This statement applies to all links and references placed in the author's own Internet offering as well as to external entries in guest books, discussion forums and mailing lists set up by the author. For illegal, incorrect or incomplete contents and in particular for damages resulting from the use or non-use of such information, the provider of the site to which reference is made is solely liable, not the person who merely refers to the respective publication via links.

3. Copyright and trademark law

The author endeavors to observe the copyrights of the graphics, sound documents, video sequences and texts used in all publications, to use graphics, sound documents, video sequences and texts created by himself or to use graphics, sound documents, video sequences and texts from the public domain.

All brand names and trademarks mentioned as part of the Internet offering and that may be protected by third parties are subject without restriction to the provisions of the applicable trademark law and the ownership rights of the respective registered owners. The mere mention of a trademark does not imply that it is not protected by the rights of third parties!

The copyright for published material created by the author remains the property of the author of the pages. It is prohibited to duplicate or use material such as graphics, sound documents, video sequences or texts in other electronic or printed publications without the express consent of the author.

4. Data protection

If the Internet offering provides an opportunity to input personal or business data (e-mail addresses, name, addresses), disclosure of this data takes place on an expressly voluntary basis on the part of the user. It is also possible to use and pay for all services offered - as far as technically possible and feasible - without providing such data or by providing anonymous data or a pseudonym.

5. Legal validity of this disclaimer

This disclaimer is considered part of the Internet offering from which you were referred to this page. Should sections or individual formulations of this text cease to comply in full or in part with the applicable law, this shall not affect the content or validity of any other part of the document.