High-quality metrology for quality control in the measuring room, production, incoming goods and development.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

Proven use for decades to spin finest yarn: planetary spinning pumps are the heart of every synthetic fibre spinning plant.

Spin finish dosing pumps do not only meter preparation fluids. They can also be used for the consistent dosing of water, perfume or even oils.

There are almost no limits to the use as a dosing pump in various industries. As a spinning pump it is only used for special applications.

Predominantly used in spinning and adhesives technology, they offer the possibility of realizing two flow rates with minimal space and one motor drive only.

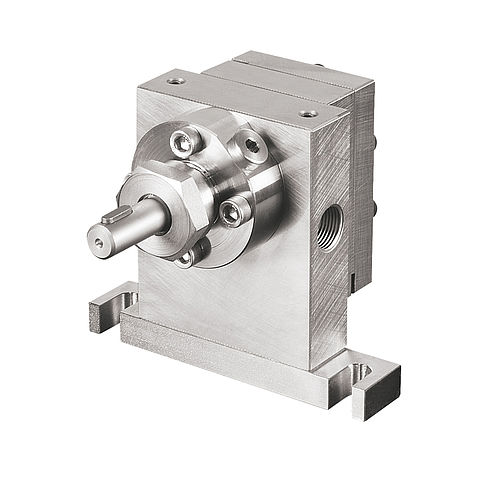

Product bores which are on both sides of the pump body allow the pump to be integrated directly into the production line.

They can be used for all applications. Direct installation in the product line does not require an additional clamping block.

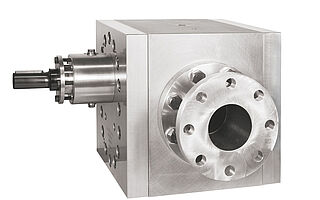

Discharge pumps ensure gentle discharge of polymer melts with low product shear. Booster pumps ensure a defined process pressure for downstream tools such as dies or extruders.

For highly accurate, low-pulsation dosing of liquids. The gear metering pumps achieve an efficient performance even at low viscosity and back pressure.

Paint metering pumps can also be used for robot applications. Even at short flushing cycles these pumps show excellent flushing results.

Solutions for material preparation, conditioning and supply to the meter mix dispense machine.

Lightweight design:

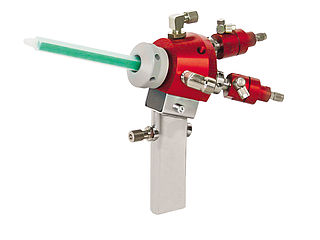

2C - 3C Meter Mix Dispense Machine for low flow rates

Our allrounder:

1C - 4C Meter Mix Dispense Machine for low to medium flow rates

Compact and efficient:

2C - 4C Meter Mix Dispense Machine with an output of up to 10 l/min

High-capacity:

2C - nC Meter Mix Dispense Machine for high material flow rates

Customised solutions:

perfectly tailored to suit your application

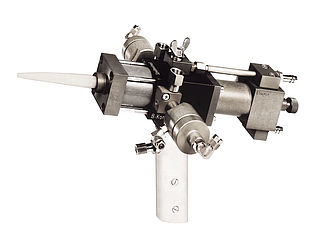

The mixing takes place exclusively through the flow movement of the components and the geometry of the mixing element.

The components are mixed by a rotating element in a mixing chamber.

The mixing takes place through the flow movement of the components in cooperation with the geometry and rotation of the mixing element.

Our locations

Mahr Metering Systems Corp.

Production site for meter mix dispense technology & gear metering pumps

High-Precision Gear Metering Pumps and Meter Mix Dispense Technology

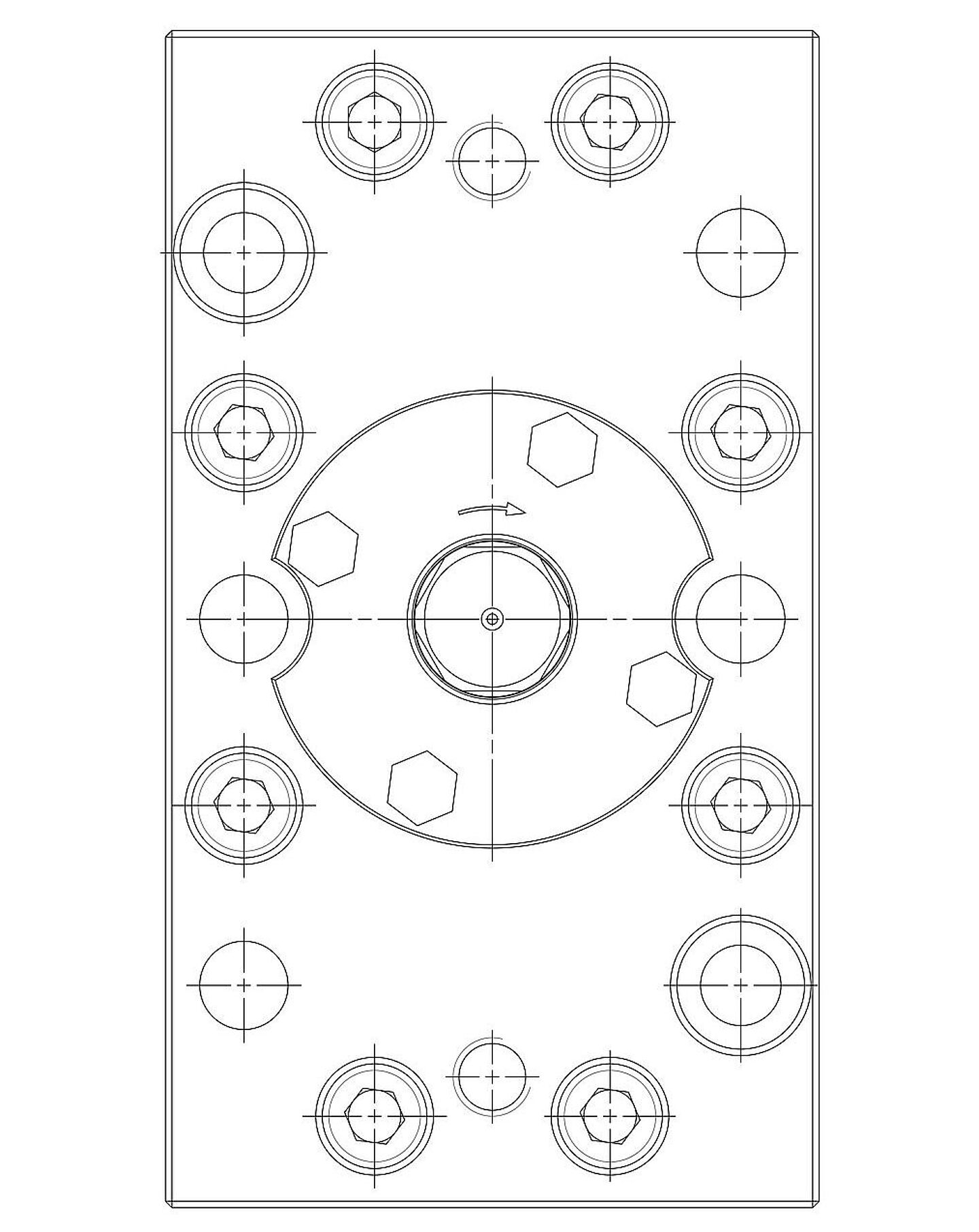

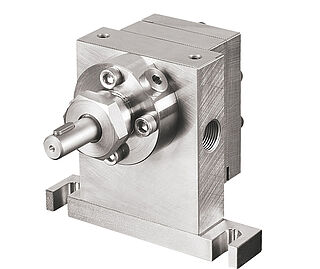

Gear metering pumps by Mahr are excellently applicable where the dosing of fluids places special demands. These requirements can be regarding the constant supply of the medium, the pressure, the temperature, the absence of corrosion, the durability of the pumps, flow rate accuracy even at high back pressures and complete operationbal reliability at high viscosity. Mahr gear metering pumps are manufactured according to the latest production technology. This technology allows the production of pumps with the smallest tolerances. Due to these small tolerances it is possible to change all single components of the pump – which offers economic advantages especially for repair work.

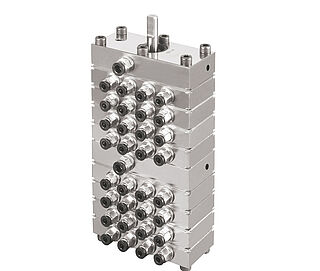

Mahr Unipre meter mix dispense technology applies wherever highest precision and efficieny in processing liquids and pastes is required. The automotive and lightweight construction industry, model making, the paper, steel and wood industry as well as the packaging industry and medical technology are just a few examples of the wide scope. The product portfolio covers solutions for material preparation and processing as well as high-performance mixing heads – manufactured according to the latest production and quality standards – and customized solutions for your application. Whether for spraying, casting or injection processes or special material processing methods such as rotational coating, centrifugal disc application or the casting of electronic components – Mahr Unipre is the competent partner for meter mix dispense technology.

Our solutions

Pumps for fiber production – precise and reliable

Feinpruef Spinning Pumps from Mahr convey the fabric from which the finest filaments are made.

High precision machines for mixing and dosing technology

Our individual machine concepts provide an optimal solution to your requirements.

Highly precise and accurate – Gear Metering Pumps

Our gear metering pumps are high-precision displacement pumps for the exact metering of liquid media.

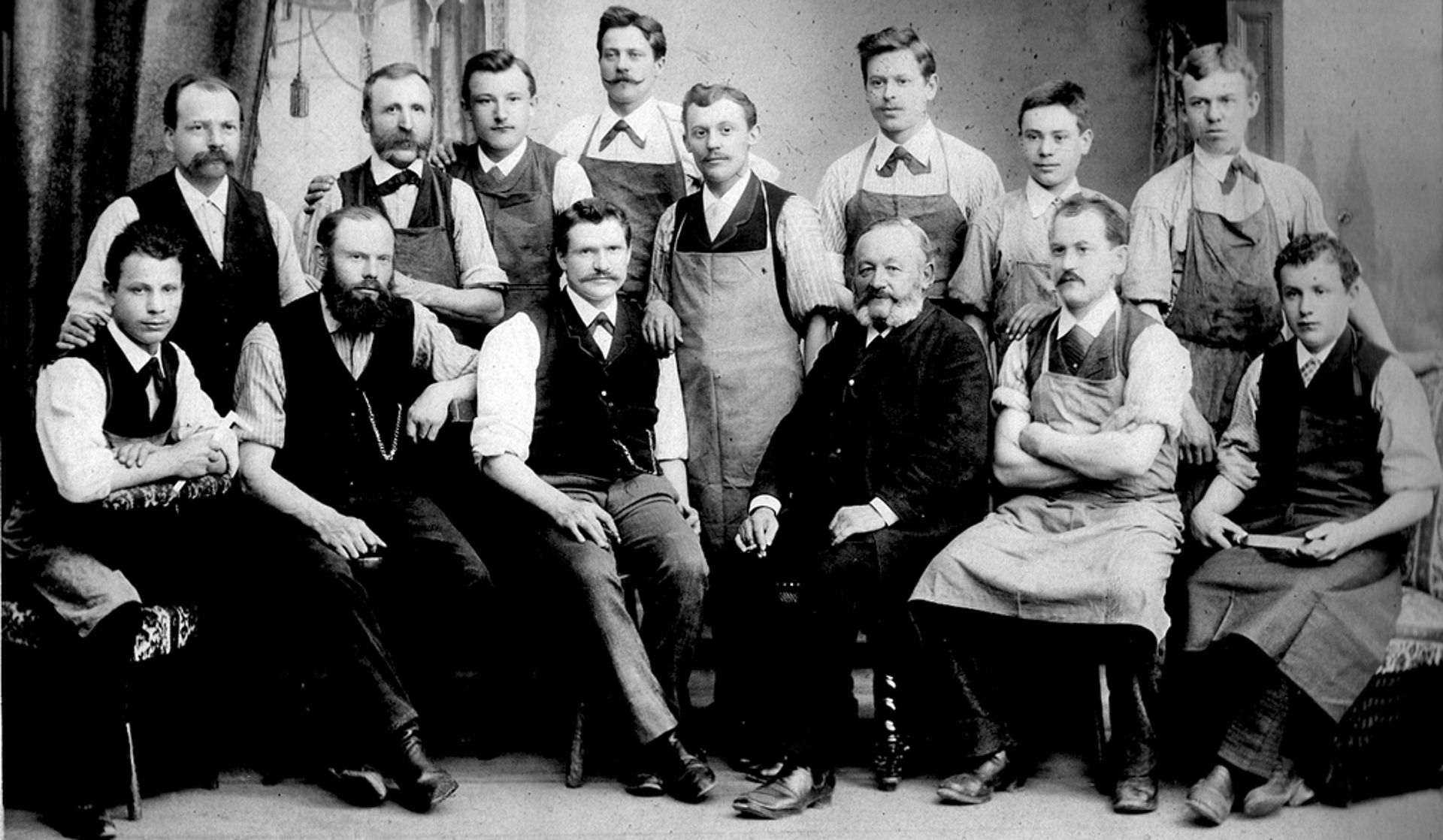

From then to now – our history

Mahr Metering Systems GmbH, formerly Mahr GmbH – Feinpruef Spinning Pumps division – is part of the Mahr Group with headquarters in Goettingen, Germany. Mahr was founded in 1861 in Esslingen by Carl Mahr, who developed the first dimensional metrology. The family business is still owner-managed today.